Digital Transformation Without Disruption

Zero Start-up Infrastructure Cost

Data Driven Predictive Analytics

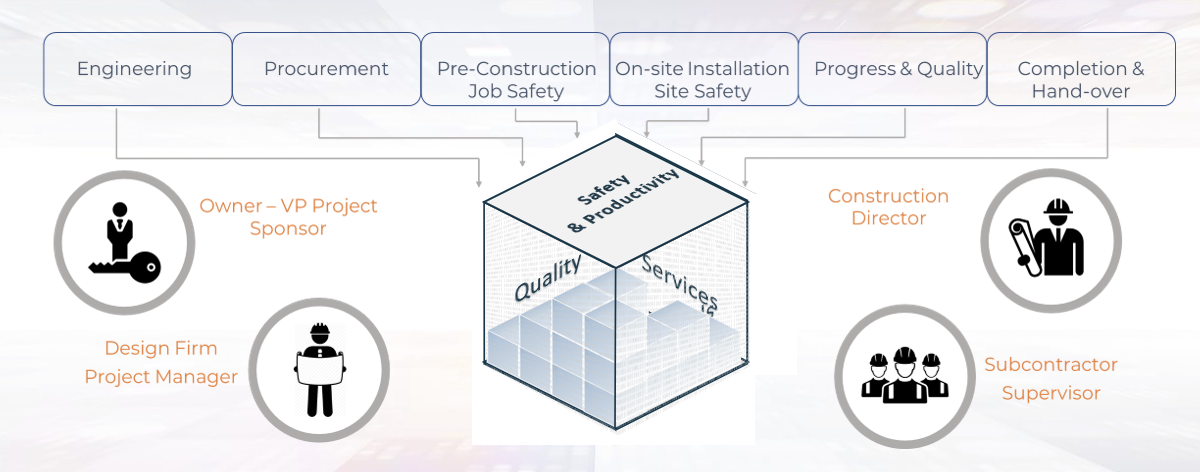

End to End Digital Project Delivery Platform with AI & GIS Technology

Learn More About How PACE OS works and the Benefits that You Get

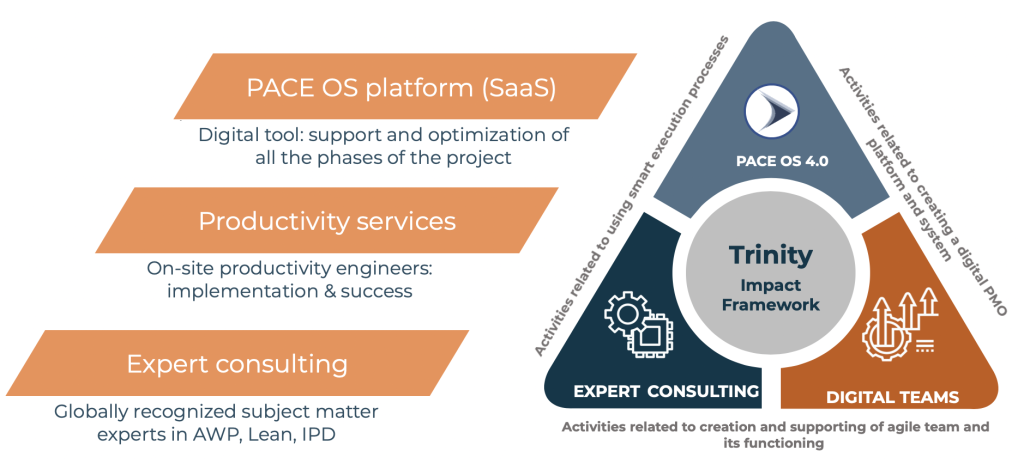

What sets us apart: THE PACE EFFECT

- PACE is a cloud-based modular platform that anyone can use – the owner, design teams or construction

- It enables instantaneous visibility and granularity to precisely know what matters the most in getting things done

We combine industry expertise with advanced technology

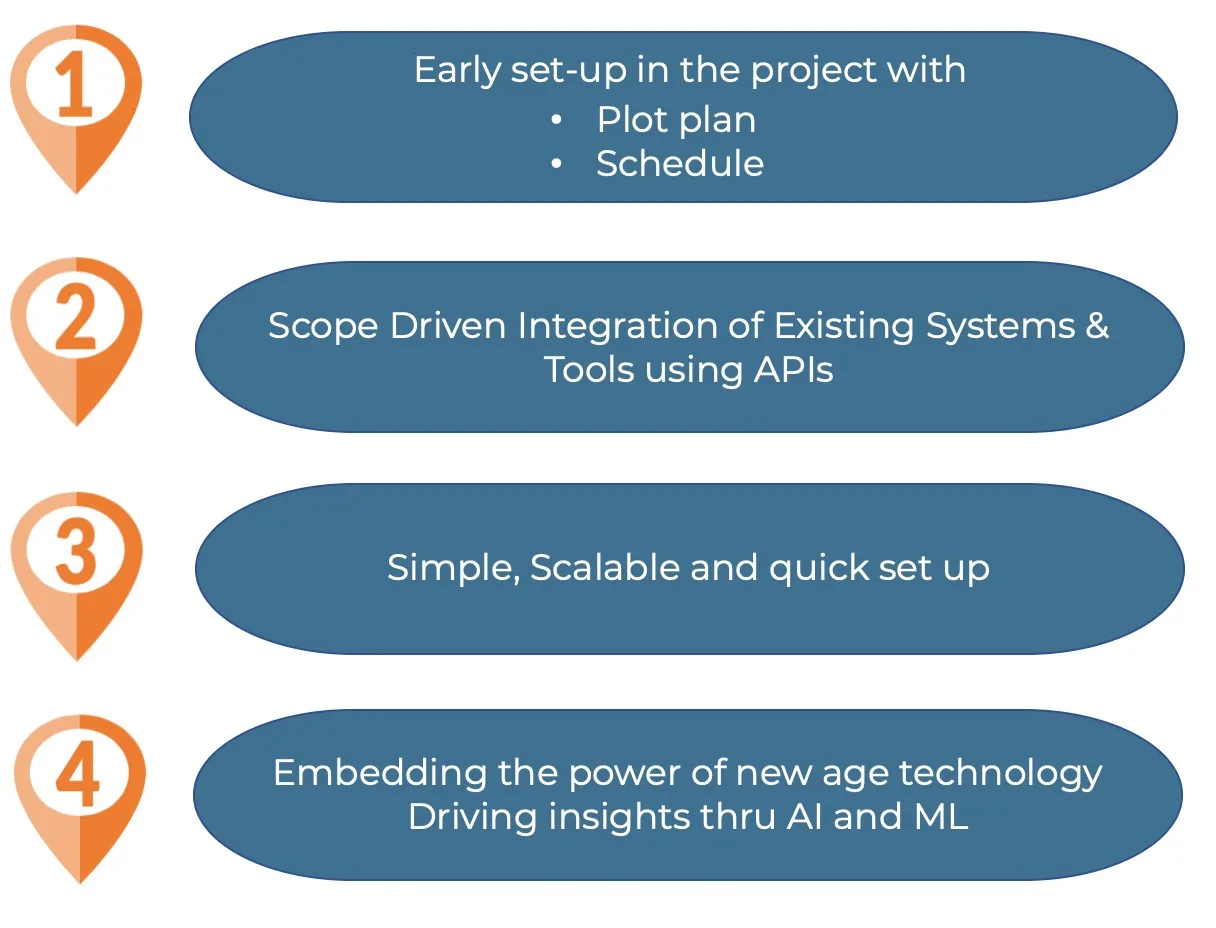

- Teknobuilt helps achieve a digital transformation beyond software, fluidly integrating with existing systems and culture from the top floor to the shop floor

- PACE OS embedded management system is a digital fusion of best practices from Construction and Manufacturing to EPC projects

Achieve project predictability & increase productivity

- Introducing the Digital Blocks of Construction™, PACE de-risks execution by advanced control and decision-driven system that enhances Surety, Speed and Savings in Project Delivery™

- The platform helps in standardization, scalability & operational discipline of “getting things done” digitally

- The collaborative power in PACE augments human intelligence (AHI) & helps in timely and proactive decision making

Ready to transform your projects?